| |

Preparing to Drill

Once the site has been selected, it must be surveyed to

determine its boundaries, and environmental impact

studies may be done. Lease agreements, titles and right-of

way accesses for the land must be obtained and evaluated

legally. For off-shore sites, legal jurisdiction must be

determined.

Once the legal issues have been settled, the crew goes

about preparing the land:

- The land is cleared and leveled, and access roads

may be built.

- Because water is used in drilling, there must be

a source of water nearby. If there is no natural

source, they drill a water well.

- They dig a reserve pit, which is used to dispose

of rock cuttings and drilling mud during the

drilling process, and line it with plastic to

protect the environment. If the site is an

ecologically sensitive area, such as a marsh or

wilderness, then the cuttings and mud must be

disposed offsite -- trucked away instead of

placed in a pit.

Once the land has been prepared, several holes must be

dug to make way for the rig and the main hole. A

rectangular pit, called a cellar, is dug around

the location of the actual drilling hole. The cellar

provides a work space around the hole, for the workers

and drilling accessories. The crew then begins drilling

the main hole, often with a small drill truck rather than

the main rig. The first part of the hole is larger and

shallower than the main portion, and is lined with a

large-diameter conductor pipe. Additional holes

are dug off to the side to temporarily store equipment --

when these holes are finished, the rig equipment can be

brought in and set up.

Setting Up the Rig

Depending upon the remoteness of the drill site and its

access, equipment may be transported to the site by

truck, helicopter or barge. Some rigs are built on ships

or barges for work on inland water where there is no

foundation to support a rig (as in marshes or lakes).

Once the equipment is at the site, the rig is set up.

Here are the major systems of a land oil rig:

Anatomy of an oil rig

Power system

- large diesel engines - burn diesel-fuel

oil to provide the main source of power

- electrical generators - powered by

the diesel engines to provide electrical

power

Mechanical system - driven by electric

motors

- hoisting system - used for lifting

heavy loads; consists of a mechanical

winch (drawworks) with a large

steel cable spool, a block-and-tackle

pulley and a receiving storage reel for

the cable

- turntable - part of the drilling

apparatus

Rotating equipment - used for rotary

drilling

- swivel - large handle that holds

the weight of the drill string; allows

the string to rotate and makes a pressure-tight

seal on the hole

- kelly - four- or six-sided pipe

that transfers rotary motion to the

turntable and drill string

- turntable or rotary table -

drives the rotating motion using power

from electric motors

- drill string - consists of drill

pipe (connected sections of about 30

ft / 10 m) and drill collars (larger

diameter, heavier pipe that fits around

the drill pipe and places weight on the

drill bit)

- drill bit(s) - end of the drill

that actually cuts up the rock; comes in

many shapes and materials (tungsten

carbide steel, diamond) that are

specialized for various drilling tasks

and rock formations

Casing - large-diameter concrete pipe that

lines the drill hole, prevents the hole from

collapsing, and allows drilling mud to circulate

|

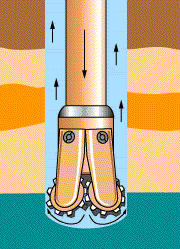

Circulation system - pumps drilling

mud (mixture of water, clay,

weighting material and chemicals, used to

lift rock cuttings from the drill bit to

the surface) under pressure through the

kelly, rotary table, drill pipes and

drill collars

pump - sucks mud from

the mud pits and pumps it to the

drilling apparatus

pipes and hoses -

connects pump to drilling

apparatus

mud-return line -

returns mud from hole

shale shaker - shaker/sieve

that separates rock cuttings from

the mud

shale slide - conveys

cuttings to the reserve pit

reserve pit - collects

rock cuttings separated from the

mud

mud pits - where

drilling mud is mixed and

recycled

mud-mixing hopper -

where new mud is mixed and then

sent to the mud pits

|

Photo courtesy

Institute of Petroleum

Mud circulation in the hole

|

Drill-mud circulation

system

- Derrick - support structure that holds the

drilling apparatus; tall enough to allow new

sections of drill pipe to be added to the

drilling apparatus as drilling progresses

- Blowout preventer - high-pressure valves (located

under the land rig or on the sea floor) that seal

the high-pressure drill lines and relieve

pressure when necessary to prevent a blowout (uncontrolled

gush of gas or oil to the surface, often

associated with fire)

back

|

|

![]()

![]()